Zurich/Alpnach, 19 August 2019 – Swiss researchers want to develop the first-ever automated machine to bioengineer personalised skin grafts for therapy. The denovoCast project, a collaboration between life science start-up Cutiss AG and CSEM, has been awarded a grant of more than CHF 800’000 by Innosuisse.

50 million people who suffer a large skin defect every year, including burn injuries, are treated with autografting, a skin grafting method older than modern medicine, that too often leaves these patients with disfiguring and debilitating scars. Scars can impair mobility and growth and require follow-up surgeries, intense homecare and psychosocial rehabilitation.

Zurich-based Cutiss AG, a spinoff of the University of Zurich, wants to offer an alternative by bio-engineering a personalized, permanent skin graft that will minimally scar after transplantation. The company has developed denovoSkin™, which is now being tested in a multi-centric phase II clinical trial.

Produce personalized skin grafts

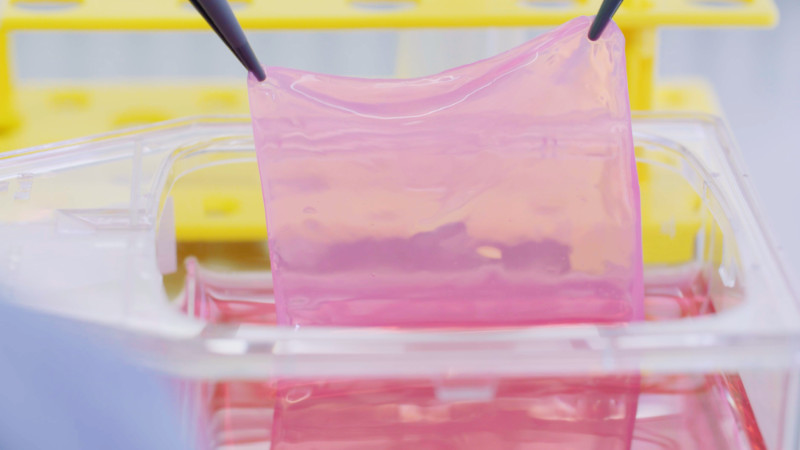

Using a stamp sized biopsy of the patient’s own healthy skin, Cutiss is able to produce several denovoSkin™ grafts in the good manufacturing practices (GMP) facility of Wyss Zurich in a fully manual process. The next step in tissue engineering is now to move from the time-consuming manual production process to automated production in order to minimize costs, ensure robustness and scale up the process. Automation is the only way to make denovoSkin really accessible to patients in need.

To support this project, the federal innovation promotion agency, Innosuisse, has awarded a grant of CHF 826’000 for the denovoCast project, a Cutiss collaboration with the Swiss research and technology organization CSEM. Over 18 months, the project will develop an innovative approach for automating the skin engineering process while preserving the quality of the tissue.

“At Cutiss, we are proud to receive this support from the Swiss government. We have a great chance to develop and bring to market the next excellent Swiss-made innovation product,” Cutiss CEO and Co-Founder Daniela Marino said. The Swiss grant comes on top of funding received from the European Union’s Horizon 2020 Program.

The bioengineered skin developed by Cutiss is unique in its biological characteristics. With its strong combination of advanced skills in automatization and bioengineering, Marino sees CSEM as the ideal partner to make this critical advance in scalability for an unmet medical need.

The global burn market alone is estimated to be worth at least one CHF billion. “We want to reach out globally, ensuring personalized skin graft production as close to the patient as possible. For that, we need to have a manufacturing process which is automated, quick, robust and standardized so that it can be easily transferred allowing the de-centralization of the manufacturing. The machine developed by CSEM will bring us one step closer to this goal,” Marino added.

Vincent Revol is the head of the CSEM team working on denovoCast. “The cutting-edge technology we are developing in this project has the potential to significantly increase the quality of life of millions of patients who suffer from skin defects, and, over the long term, may also be applied to other tissue engineering processes such as cornea or mucosa,” he said.

A Swiss made solution

The end result envisaged by Cutiss is a skin-tissue producing machine that will be placed in multiple manufacturing facilities, starting off with Zurich. The machine, made in Switzerland, would require minimal user interaction.

“The main challenge will be to produce skin tissues on a larger scale, on a commercially relevant scale. Burn patients need a lot of new skin, as quickly as possible. We have a team working on automation and liquid handling, and another team working on the customized labware where the skin graft will be engineered.” Revol said.

Cutiss AG, with a team of 19 people, has excelled on the start-up circuit, winning several awards and the backing of major investors. The company has secured 17 million CHF in funding since its founding in 2017.