CUTISS is delighted to announce that Innosuisse, the Swiss Innovation Agency, has awarded the company a CHF 2.5 million grant to advance our pioneering automation program.

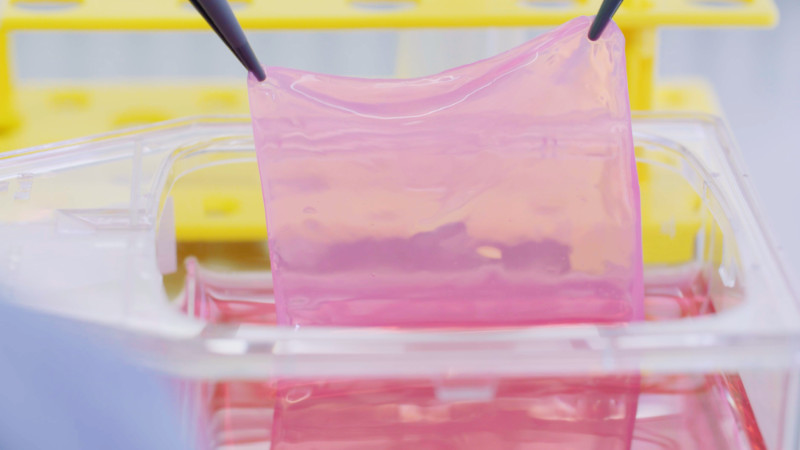

This grant will support the industrialization of denovoCast™, the world’s first machine that can bio-engineer large, personalized skin tissue grafts, in a fully closed way.

This is yet another stamp of quality approval for our ambitious and unique automation program, and we are grateful to Innosuisse and their continued support.

Taking the denovoCast™ machine to clinical readiness

CUTISS unveiled the first denovoCast™ machine in 2021, demonstrating the feasibility of automating the bio-engineered skin manufacturing process. The machine was developed in collaboration with Innosuisse and CSEM.

Since then, the machine has undergone R&D testing at CUTISS and we are now ready to start the process of industrialization that will take denovoCast™ to clinical readiness at the service of adults and children with severe skin injuries, such as deep burns.

Automation is key to scale up production of denovoSkin™

CUTISS is working to scale-up the production of denovoSkin™ through automation. The company has developed its own unique approach to bioengineering human skin tissue composed of three modules: cell isolation (Semotiss™), cell expansion (Quantum®), and skin tissue formation (denovoCast™). Starting form a patient’s biopsy and working in sequence, the modules produce the personalized dermo-epidermal skin graft denovoSkin™.